warman 8 6 ah slurry pump manufacturers

Latest articles

Mixers can also help agitators when pumping very dense particles. In applications where the tank is small and/or where pumping is desired to lower the water level in the tank, a slurry pump with an internal cooling system should be considered to avoid overheating of the stator (when the water level gets low). When pumping sediment from a dam or lagoon, consider the use of a raft unit, which is a submersible device. Agitators are recommended, as well as one or more mixers that can be mounted on the raft or pump to resuspend particles for successful pumping of particles.

warman 8 6 ah slurry pump manufacturers...

warman 8 6 ah slurry pump manufacturers 【warman 8 6 ah slurry pump manufacturers】

Read MoreChoosing the right pump for your slurry is critical to getting the most out of it. Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear caused by abrasive slurries. Compared to low-viscosity liquid pumps, target=_blank title=Slurry Pump>slurry pumps are typically larger and often require more horsepower to operate because they are less efficient. Bearings and shafts must also be more robust and durable.

warman 8 6 ah slurry pump manufacturers...

warman 8 6 ah slurry pump manufacturers 【warman 8 6 ah slurry pump manufacturers】

Read MoreQuenching is defined as the introduction of a neutral fluid (usually water or steam) into the atmospheric side of the seal to prevent the formation of solids that may interfere with movement or be used for other purposes.

warman 8 6 ah slurry pump manufacturers...

warman 8 6 ah slurry pump manufacturers 【warman 8 6 ah slurry pump manufacturers】

Read MoreWhy would maintenance personnel want to adjust a high-speed rotating impeller to a static lining component while the unit is running? Even if interlocking devices are used to prevent static and non-static components from coming into contact, how credible are these features and what are the implications for pump wear parts, bearings and motors if these two components come into contact?

warman 8 6 ah slurry pump manufacturers...

warman 8 6 ah slurry pump manufacturers 【warman 8 6 ah slurry pump manufacturers】

Read MoreSlurry Pump

warman 8 6 ah slurry pump manufacturers...

warman 8 6 ah slurry pump manufacturers 【warman 8 6 ah slurry pump manufacturers】

Read MoreSubmersible Slurry Pump

warman 8 6 ah slurry pump manufacturers...

warman 8 6 ah slurry pump manufacturers 【warman 8 6 ah slurry pump manufacturers】

Read More-When pumping abrasive slurries, it is essential to use wear-resistant components with a high chromium content. But more is not always better - above 25%, the impeller becomes brittle.

warman 8 6 ah slurry pump manufacturers...

warman 8 6 ah slurry pump manufacturers 【warman 8 6 ah slurry pump manufacturers】

Read MoreIf you want to know more information about the best heavy duty slurry pump, welcome to >contact us today or request a quote.

warman 8 6 ah slurry pump manufacturers...

warman 8 6 ah slurry pump manufacturers 【warman 8 6 ah slurry pump manufacturers】

Read MoreReduced inventory

warman 8 6 ah slurry pump manufacturers...

warman 8 6 ah slurry pump manufacturers 【warman 8 6 ah slurry pump manufacturers】

Read MoreChoosing The Right Slurry Pump For Your Application

warman 8 6 ah slurry pump manufacturers...

warman 8 6 ah slurry pump manufacturers 【warman 8 6 ah slurry pump manufacturers】

Read More

Popular articles

- In addition, a new level of complexity is added to an otherwise simple machine. Other parts must now be inventoried and training beyond basic spanner turning is required. When it comes to pumping rock and some of the world's most abrasive materials.

- 2.Pumping slurries poses several challenges and problems, but with proper engineering and equipment selection you can experience many years of worry-free operation. It's important to work with a qualified engineer when selecting a slurry pump because slurries can wreak havoc on a pump if not properly selected.

- WA series target=_blank title=Heavy-Duty Slurry Pump>heavy-duty slurry pump is cantilevered, horizontal, natural rubber or hard metal lined centrifugal slurry pumps. They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industry department.

- Any type of impeller can be used in slurry applications, but closed slurry pump impellers are more common because they are high efficient and abrasion Resistance,. Open slurry pump impellers are usually used well for high concentration solids as they are less likely to clog. For example, the small fibers in paper stock which, in high densities, may have a tendency to clog the impeller. Pumping slurry can be difficult.

- Slurry Pump Selection

- Slurry Pump VS Mud Pump

Latest articles

-

Submersible Slurry Pump

-

Mud pumps are mainly used for drilling, pharmaceutical, brewing, paper, and other industries, which used to transport suspension.

-

WY type pump casing is made of abrasion resistant metal, impeller material can be abrasion resistant metal or rubber. The submerged parts of WYJ are all lined with rubber, for transfer corrosive slurry.

-

Caution: A common mistake is to over-pressurise the box and damage the expensive mechanical seal.

-

In AIER® slurry pumps, WY & WYJ sump pump are vertical centrifugal slurry pump, submerged for transfer abrasive, coarse particles and high density slurry. When working, it needs no seal water or any kind of seal. It can work well as well when suction volume is not enough.

-

How Slurry Pumps Differ From Standard Pumps?

Links

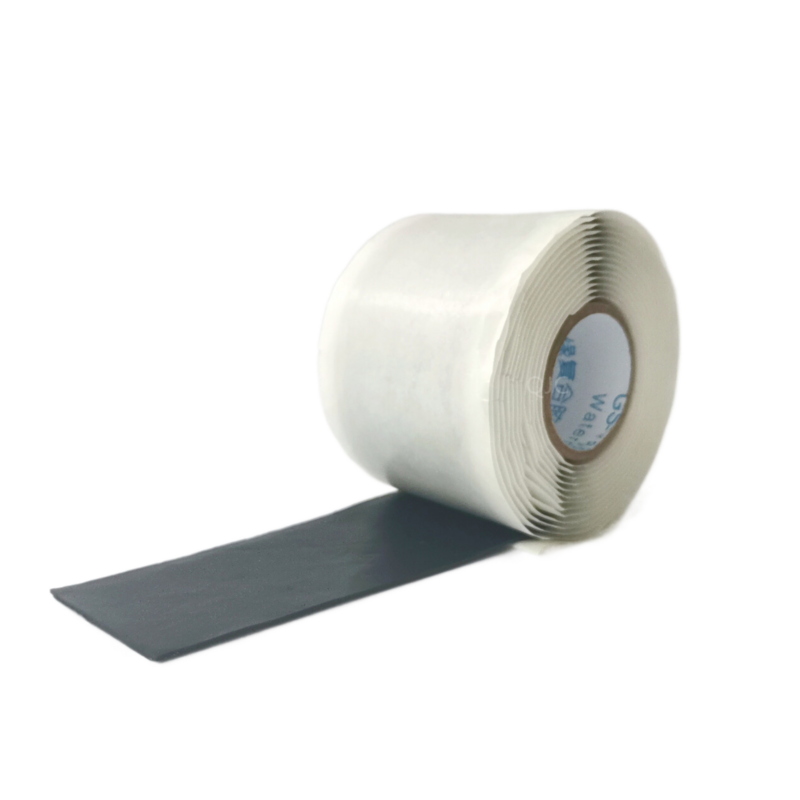

- Another significant advantage of self-amalgamating electrical tape is its excellent electrical insulation properties. It is made from high-quality polymers that provide a high dielectric strength, ensuring that electricity flows safely and efficiently through the repaired area. This makes it suitable for use in a variety of applications, including wiring, splicing, and insulating electrical components.

- The primary function of gym floor tape is to provide clear demarcations. In a bustling gym environment, where various exercises and activities coexist, the tape serves as a visual guide. It separates weightlifting areas from cardio zones, defines the boundaries of basketball courts, and indicates designated spots for group classes. This not only prevents accidental collisions but also streamlines gym traffic, allowing members to move around with ease and focus on their workouts without distractions.

It is made from materials that are specifically designed to prevent the flow of electricity, ensuring that wires remain safe and secure It is made from materials that are specifically designed to prevent the flow of electricity, ensuring that wires remain safe and secure

It is made from materials that are specifically designed to prevent the flow of electricity, ensuring that wires remain safe and secure It is made from materials that are specifically designed to prevent the flow of electricity, ensuring that wires remain safe and secure cloth wiring harness tape. This makes it an essential component in any electrical system where safety is a top priority.

cloth wiring harness tape. This makes it an essential component in any electrical system where safety is a top priority.The tape is also known as ‘F4 tape’, ‘tommy’, ‘rescue’, ‘magic tape’ and ‘fix-it tape’.

It is widely used in manufacturing plants, chemical facilities, and oil refineries to seal and protect vital infrastructure It is widely used in manufacturing plants, chemical facilities, and oil refineries to seal and protect vital infrastructure

It is widely used in manufacturing plants, chemical facilities, and oil refineries to seal and protect vital infrastructure It is widely used in manufacturing plants, chemical facilities, and oil refineries to seal and protect vital infrastructure

Small, deliberate steps should be taken daily, reinforcing positive habits and gradually moving towards our set targets Small, deliberate steps should be taken daily, reinforcing positive habits and gradually moving towards our set targets

Small, deliberate steps should be taken daily, reinforcing positive habits and gradually moving towards our set targets Small, deliberate steps should be taken daily, reinforcing positive habits and gradually moving towards our set targets